프리미어카지노, 카지노친구와 함께하는 즐거운 카지노사이트 이용방법 소개

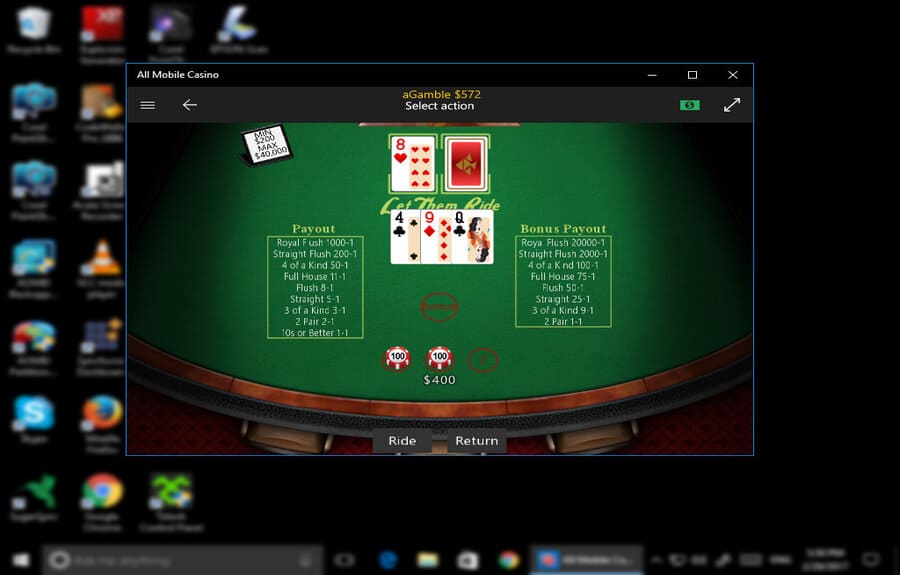

프리미어카지노는 한때 많은 이용자들 사이에서 입소문을 타고 인기를 끌었습니다. 그러나 이용자들이 안심하고 즐길 수 있는 안정적인 카지노를 찾는 것은 어려운 과정입니다. 이에 카지노친구 플랫폼은 이용자들에게 안전하고 검증된 업체를 추천하여 이러한 고민을 해결하고자 합니다. 카지노친구는 다양한 카지노 업체들을 검증하고 그 중에서도 프리미어카지노를 강력하게 추천합니다. 프리미어카지노는 안전하고 신뢰할 수 있는 업체로, 이용자들에게...